Benefits And Surface Styles for Different Aluminum Finishing Types

Surface finishing is essential in aluminum manufacturing, impacting appearance, performance, and durability. It enhances properties like wear resistance, electrical insulation, and reflectivity, while preventing corrosion by keeping contaminants away. A well-finished surface ensures longer-lasting products.

10 Popular Aluminum Finishes

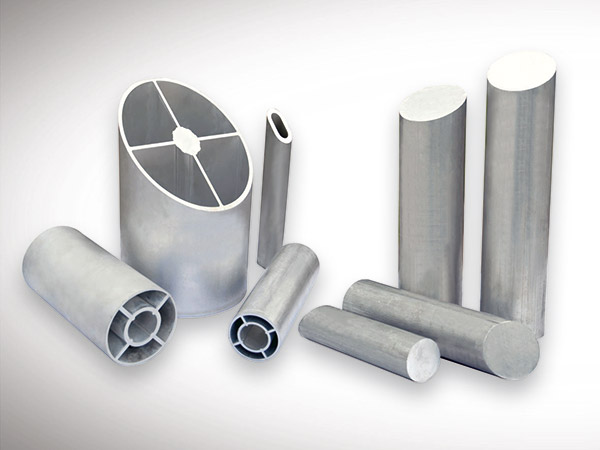

1. As-Machined Finish

This is the raw, untouched look of aluminum straight from the mill, this finish is cost-effective and suitable for parts without special coating needs. Surface roughness ranges from Ra 0.2 to 3.2 µm, but you might see some visible tool marks.

2. Anodizing

Anodizing is a popular choice for aluminum. This electrochemical process creates a durable, corrosion-resistant oxide layer bonded at the molecular level. It offers vibrant colors and long-lasting protection against wear.

3. Powder Coating

If you want your aluminum products to look good and stay protected, powder coating is the way to go. Using an electrostatic process, powder coating provides a durable, environmentally friendly finish. It's ideal for decorative and protective applications but may have a slightly rough texture.

4. Alodine Finish (Chem Film)

A cheaper alternative to anodizing, Alodine creates a thin oxide layer through chemical treatment. It's suitable for parts requiring electrical conductivity. It's a good balance between cost and performance.

5. Bead Blasting

This mechanical finish uses high-pressure beads to create a smooth, satin-like surface. It's ideal for semi-polished or dull finish retaining the aluminum's natural color. It's a great choice if you want a semi-polished look without going overboard.

6. Electroplating

Depositing a thin metal layer via electrolysis, electroplating enhances strength, conductivity, and corrosion resistance. It's suitable for parts that need to withstand harsh conditions or look extra fancy.

7. Polishing

Creating a reflective, shiny surface. It creates a reflective surface that protects against contamination and oxidation. This finish is perfect for custom parts that need to look their best, like those used in medical equipment or high-end interiors. But it may degrade over time due to environmental exposure.

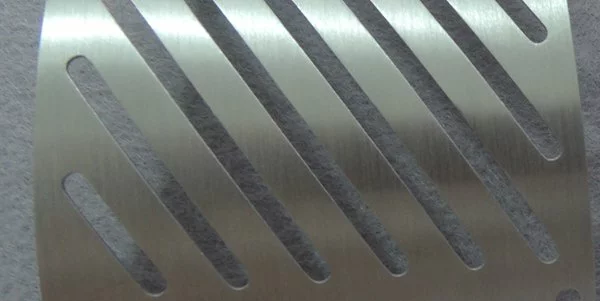

8. Brushing

An abrasive brush moves over the surface, brushing creates a textured, directional finish that adds luxury and improves scratch resistance. Suitable for both indoor and outdoor applications.

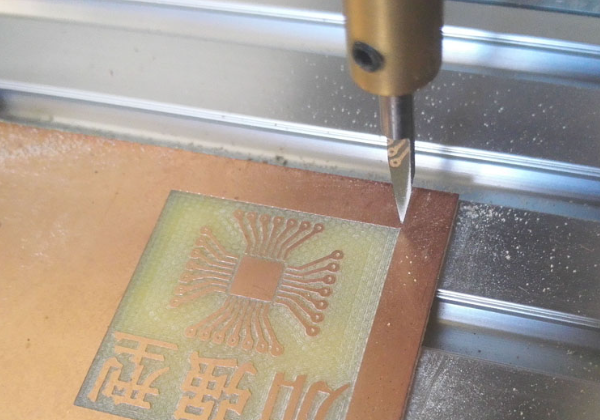

9. Laser Etching

Using a laser beam, this technique creates precise, permanent engravings. A laser beam carves deep, permanent marks or engravings into the surface. It's incredibly precise and used in industries where accuracy matters, like aerospace, medical, and automotive.

10. Bright Dipping

The parts are dipped in acid to create a polished, shiny surface. This acid-based process gives aluminum a mirror-like finish, perfect for sleek, sophisticated products. However, it involves hazardous chemicals and is not suitable for all aluminum types.

Surface Effects and Styles for Aluminum

1. High Gloss: shiny and reflective, ideal for sleek designs but shows fingerprints easily.

2. Satin: soft sheen, hides flaws well, suitable for furniture and architecture.

3. Matte: dull and non-reflective, easy to clean, and durable.

4. Metallic: luxurious look, can be tinted to resemble other metals like brass or copper.

Each aluminum finish has unique benefits. Anodizing is often considered the best due to its durability and long-lasting protection against corrosion and wear.

Anodizing is also one of main way of surface finishing in our company, we have an independent anodizing workshop to ensure our suspensions have excellent corrosion and wear resistance. In addition, our universal surface finishing methods include powder coating, alodine Finish, polishing and laser Etching. These processing methods make our products not only beautiful in appearance but also have a long service life.

If you need different types of products, our customized services can better meet your demands. We can customize matte, high glossy or satin appearances, and can also laser engrave your unique logo. If you need, please put forward your requirements when customizing the products, we will provide professional advice and reply.